-

Magnesium Sulphate Salt

-

Ammonium Sulphate Chemical

-

Sodium Carbonate Chemical

-

Calcium Chloride Chemical

-

Magnesium Chloride Chemical

-

Magnesium Oxide

-

Raw Material Chemicals

-

Sodium Metabisulfite Chemical

-

Sodium Bicarbonate Chemical

-

Poly Aluminium Chloride

-

Aluminium Sulphate Salt

-

Ferrous Sulfate Chemical

-

Industrial Salt

-

Sodium Sulfite

-

Sodium Sulphate

-

Agriculture Fertilizers

-

Jaime GonzalezBuilding Chemistry, Shaping Tomorrow! We trust that JIUCHONG will continue to deliver excellent products and services, ensuring long-term mutual success.

Jaime GonzalezBuilding Chemistry, Shaping Tomorrow! We trust that JIUCHONG will continue to deliver excellent products and services, ensuring long-term mutual success.

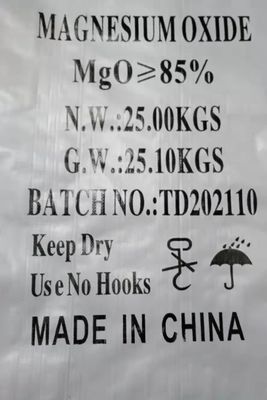

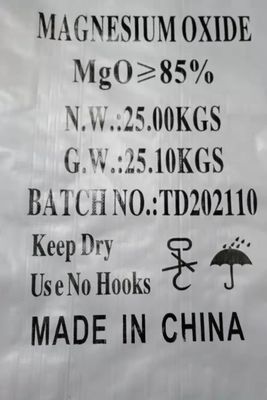

Light Yellow Magnesium Oxide For MGO Board Fireproof Board Wall Panel Fused

| Name | Magneisum Oxide | CAS | 1309-48-4 |

|---|---|---|---|

| EINECS | 215-171-9 | HS Code | 2519909100 |

| Specification | 65%~95% | Usage | Building Board Desulphurization |

| Highlight | Light Yellow magnesium Oxide,Light Yellow MGO chemical |

||

MGO Board Fireproof Board Wall Panel Fused Magnesium Oxide Light Yellow

Description:

White fine powder. No odor. Due to different preparation methods, there are two types: light and heavy. Strong refractive index in the visible and near-ultraviolet range. Exposed in the air, it is easy to absorb water and carbon dioxide, gradually becoming basic magnesium carbonate. It is lighter and faster than heavy, and combines with water to form magnesium hydroxide, which shows a slightly alkaline reaction. The pH of the saturated aqueous solution is 10.3. But it is highly soluble in dilute acids and slightly soluble in pure water, increasing its solubility due to the presence of carbon dioxide. Insoluble in ethanol. Relative density (d254) 3.58. Melting point 2852 ℃. Boiling point 3600 ℃.

Applications:

Fireproof Board

Magnesium Oxide Fireproof Board, MGO board, dragon board is the building material widely used in the consturction area. The stable magnesium colloid is reinforced by middl alkali glass fiber net and stuffed by light material then becomes new frameless decorative material 100% no Asbestos Contained and no radioactivity.

What is the MGO board?Why is MGO board a better building and decoration material?

MGO board named as magnesium oxide board,it is a new fireproof building and decoration material.It has a high temperature, flame retardant, sound-absorb, Anti-seismic, waterproof and moisture proof , anti-moth, light and anti-corrosion, non-toxic ,tasteless ,non-polluting, It can be directly on the paint, veneer directly ,pasting tile. Its surface has good coloring. High strength, resistance to bending, toughness, It can be sawed,nailed, glued, extremely convenient decoration,no radioactivity.Magnesia boards are used in place of traditional gypsum drywall as wall and ceiling covering material and sheathing,as well as in a number of other construction applications.

Desulfurization

Magnesium oxide desulfurization technology is a desulfurization process with a maturity second only to the calcium method. The magnesium oxide desulfurization process has been widely used worldwide, with over 100 projects in Japan and 95% of power stations in Taiwan using the magnesium oxide method. In addition, it has been applied in the United States, Germany, and other places, and currently has been applied in some regions of China.

The boiler flue gas is fed into the pre cooling section of the absorption tower by an induced draft fan, cooled to a suitable temperature, and then enters the absorption tower. It reacts with the absorption slurry in the reverse flow upwards to remove sulfur from the flue gas. A mist eliminator is installed on the top of the absorption tower to remove small mist droplets carried in the clean flue gas. The clean flue gas is discharged into the chimney after passing through a mist eliminator to reduce the moisture in the flue gas. Dust and dirt attached to the demister will cause blockage of the demister and increase pressure loss of the system. The demister washing pump needs to provide industrial water for spray cleaning of the demister.

Fused Magnesia

Fused magnesia is produced from natural magnesite or high purity calcined magnesite grain, which is fused in arc furnaces. The product has high purity, crystal grain, compact structured, strong slag resistance and good thermal shock stability. It is a kind of excellent high temperature electrical insulation material and is also used to make high quality magnesite bricks, magnesia carbon brick and the important raw materials for amorphous refractory.

(1)Industry usage

The structure of fused magnesia is in tact, has good stability, high temperature resistance, strong corrosion resistance. It is the most important raw material of refractory used in the manufacturing of all kinds of magnesite brick, magnesium aluminum brick, ramming material and more. Fill burden material which contain more impurities, is used for paving steel furnace bases.

(2)Electronics industry

Specifications:

| Application | Specification |

| For Board | 65%~85% |

| For Desulphurization | 65%~95% |

| Fused | ≥96% |

Feature Advantage:

Used in metallurgy, smelting, manufacturing of advanced magnesium bricks, refractory materials, and moisturizing materials. It is also widely used in rubber, rubber sheets, rubber products, pharmaceutical industry, food industry, plastic sheet promoter, plasticizer for fiberglass and surface coating paint for silicon steel sheets, paper production, steel ball polishing, leather treatment, insulation materials, oils, dyes, ceramics, desiccants, resins, flame retardants, etc.

Package

![]()

![]()